Laser Cladding is a complex process, which is governed by a large number of parameters (e.g. powder flow rate, laser power, travel speed) which are typically used to control the process properties.

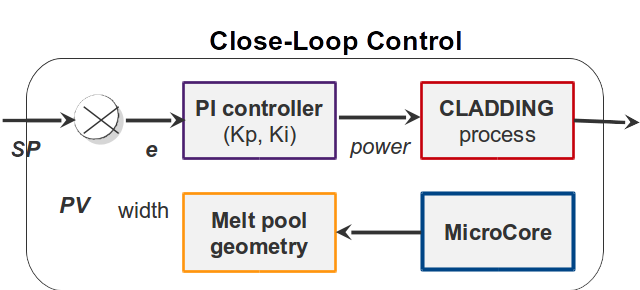

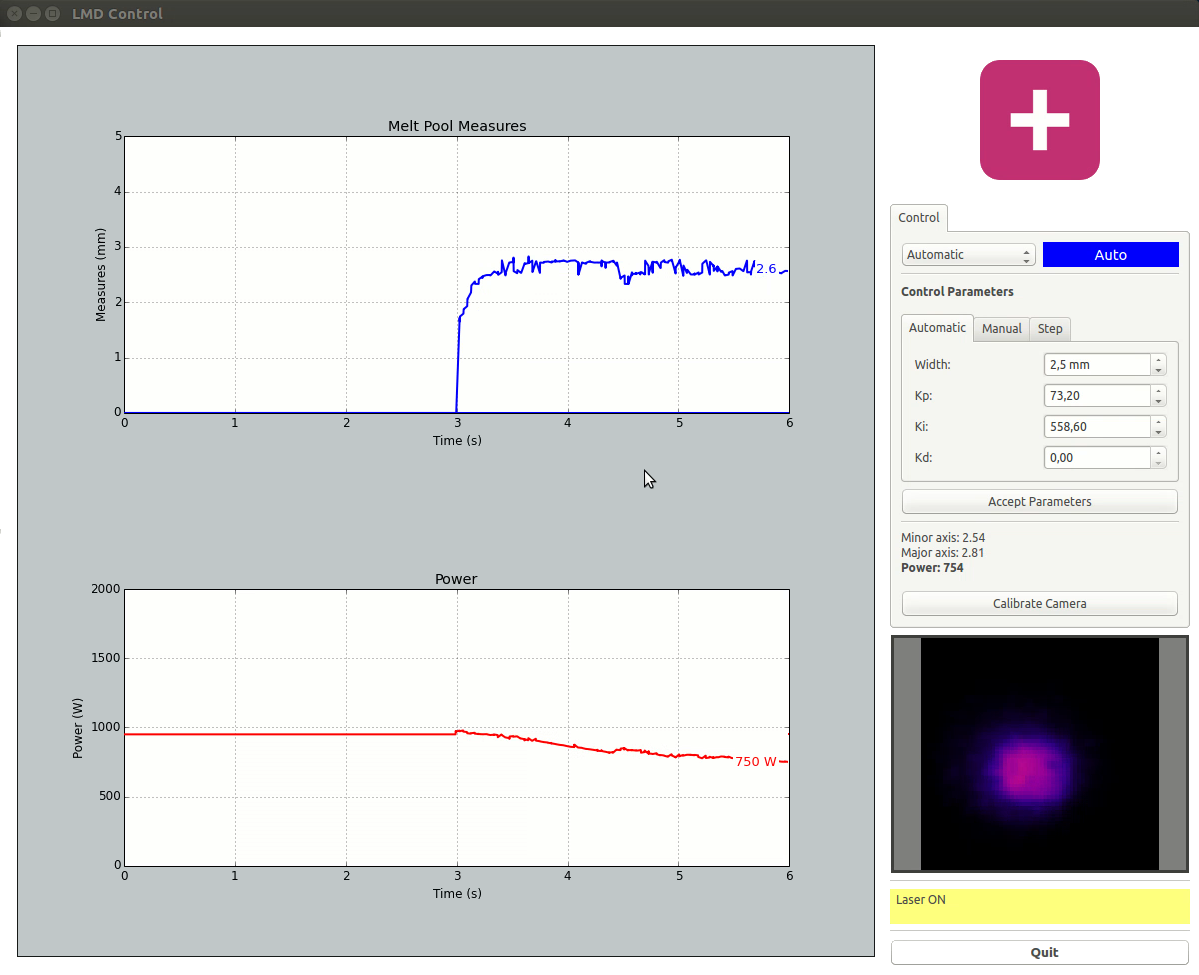

Using a high speed infrared sensing camera is possible to measure the melt pool geometry and control the laser power to reduce the heat input and the effects of thermal and geometrical variations.

This closed-loop control solution bases on high-speed SWIR/MWIR coaxial monitoring. Using a cost effective camera provided by NIT Europe which is able to provide high-speed thermal information with an uncooled solution in the spectral range from 1um to 5 um.

|

Software shared in OpenLMD is intended for research and does not have any guarantee. Contact with NIT Europe for commercial information. |

Introduction

A simple PI controller is fed by the geometrical measurement calculated from the MWIR image. This measurements assumes that the melt pool can be estimated as an elliptical shape.

Contact

Jorge Rodríguez-Araújo (jorge.rodriguez@aimen.es)

Copyright 2016-2017 - AIMEN Technology Center