OpenLMD is a novel open-source solution for on-line multimodal monitoring and control of Laser Metal Deposition (LMD). The solution is also applicable to a wider range of laser-based applications that require on-line control (e.g. laser welding).

Built on ROS (Robot Operating System), the modular approach provided by OpenLMD pursues the deployment of new algorithms beyond the state-of-the-art in real facilities, fixing common interoperability and standarization issues. Moreover, it takes advantage from open source and most advanced robotics, vision, and machine learning research.

As a result, OpenLMD delivers significant advantages over existing monitoring and control approaches, such as improved scalability, and multimodal monitoring and data sharing capabilities.

OpenLMD enables direct deployment of complex multimodal monitoring and control solutions from research to actual industrial facilities.

OpenLMD arises from AIMEN's development efforts on several Laser Metal Deposition (LMD) projects, focus on building and repairing large and complex metal parts - with no defects -. These efforts have been mainly driven by the MAShES project, the PROPER assesment from the LASHARE project and the CyPLAM experiment from the FORTISSIMO2 project.

Introduction

Laser Metal Deposition (LMD) is an additive laser deposition technique focused on direct manufacturing of metal parts, through the successive deposition of melted tracks layer-by-layer, building the component directly from its CAD model.

Unlike Selective Laser Melting (SLM), consisting on the deposition of powder layers and their subsequent laser melt (mainly used for rapid prototyping), LMD only adds the required material.

This Additive Manufacturing (AM) technique works on current processing technology, known as Laser Cladding, commonly used for repair of metal components. This makes LMD a promising technique for retrofitting of current industrial facilities towards the digital factory (Industrie 4.0).

Getting Started

You only must install ROS and clone OpenLMD projects on a computer running Ubuntu 14.04.

- To install ROS Indigo followindg the instructions in the next link (http://wiki.ros.org/indigo/Installation/Ubuntu).

- To configure a ROS workspace following the indications in (http://wiki.ros.org/catkin/Tutorials/create_a_workspace).

- To clone the OpenLMD repositories in (https://github.com/openlmd).

Moreover, you must add the line source ~/catkin_ws/devel/setup.bash

at the end of your ~/.bashrc file for loading your workspace by default.

When the instalation is completed, you can launch the MAShES

workcell environment:

$ roslaunch mashes_robviz robviz.launch

Some datasets for testing and development have been shared on ZENODO platform as "Laser cladding multispectral coaxial monitoring" (https://zenodo.org/collection/user-mashes).

Subprojects

|

ROS-based LMD Integration Integration of AIMEN's LMD robotized cell based on ROS. |

|

3D Geometrical Monitoring 3D on-line monitoring (point cloud) for LMD robotized cells. |

|

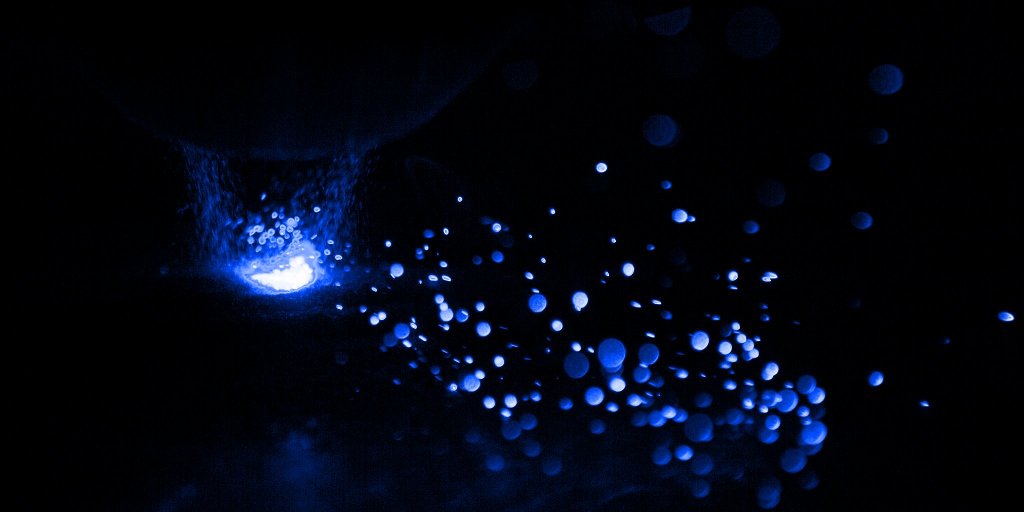

Multimodal Monitoring Image-based multimodal monitoring for Laser applications. |

|

Off-line Robot Path Planning Simple off-line path planning for robotized LMD automation. |

|

Real-Time Process Control Image-based asynchronous RT close-loop control for LMD systems. |

|

Adaptive LMD Process Planning Adaptive path planning for an automatic repair of large and complex metal parts. |

|

Big Data Registration Big data registration for LMD adaptive parametric control (based on Big Data and Deep Learning). |

Contact

Verónica Panadeiro-Castro (veronica.panadeiro@aimen.es)

Baltasar Lodeiro-Señarís (baltasar.lodeiro@aimen.es)

Jorge Rodríguez-Araújo (jorge.rodriguez@aimen.es) - https://www.linkedin.com/in/jraraujo

Copyright 2016-2017 - AIMEN Technology Center